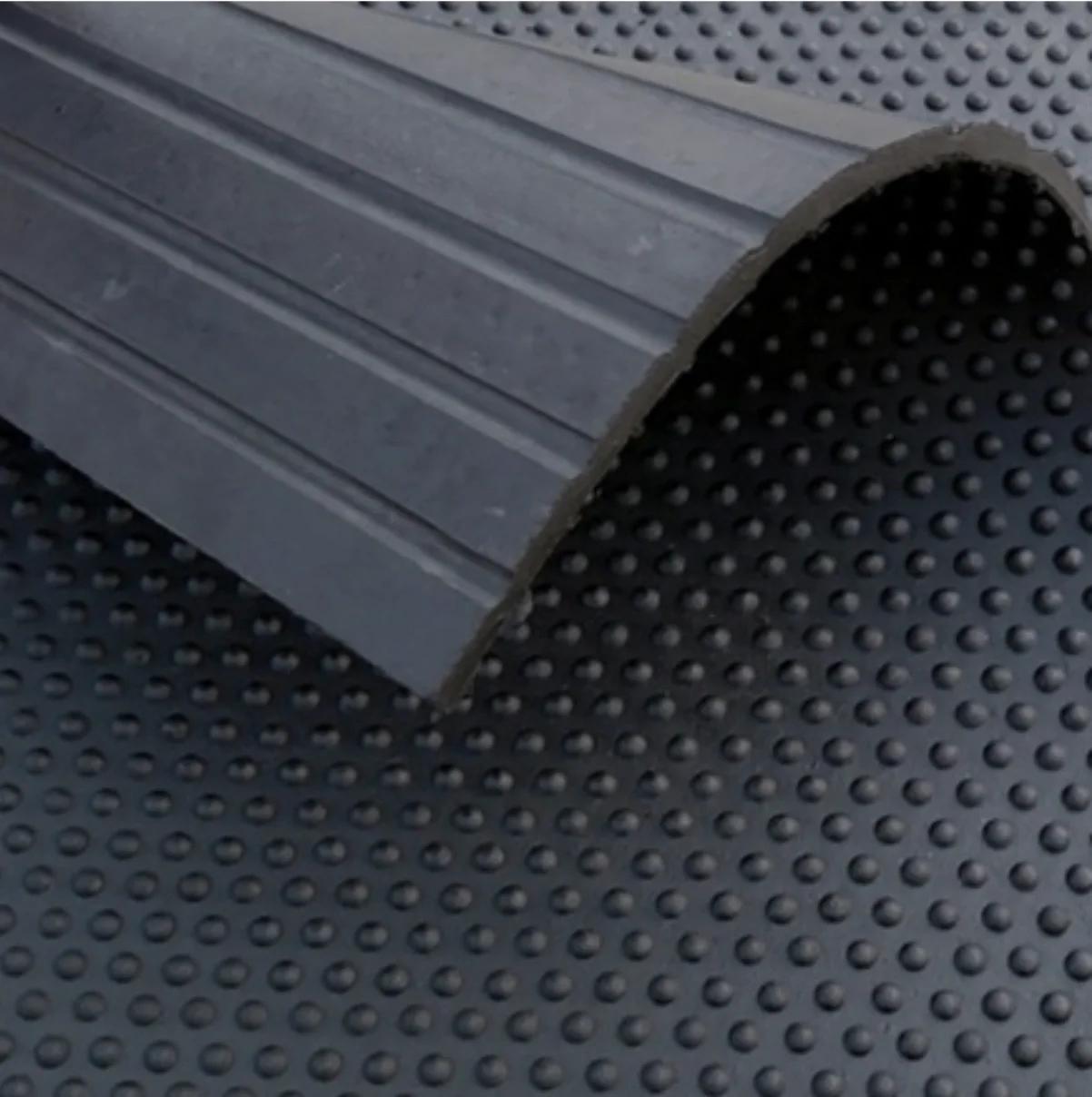

Insulation rubber sheet is a product used in industry, so what are the ingredients of this product and some other rubber products are different? Next, the staff of our factory will answer this question for you. I hope you can have more understanding and understanding of our products.

Vulcanization is one of the main processes in the processing of rubber products. In the exchange of raw rubber and vulcanization under the conditions of heating or irradiation, chemical reactions occur, making the rubber become the size molecule of the three-dimensional network structure from the size of the linear structure, resulting in a significant change in the physical and mechanical properties of the delicate, as well as other properties. With the development of science and technology vulcanization and high temperature is no longer the necessary conditions for vulcanization, some rubber can be vulcanized at a lower temperature, even at room temperature, some can be exchanged by physical methods, the use of rubber without the need for vulcanization agent to make any kind of rubber sheet rubber data is the main effect, There are various collaborations that come together to form a multi-group system of data. Plasticizer can be the rubber material has the necessary process function, can also reduce the production cost, antioxidant can improve the aging resistance of vulcanized rubber, and the aging of various varieties of protective effect, and then extend the service life of rubber sheet.

The use of Insulation rubber sheet is relatively wide range, and the amount is also relatively large, is a product to be used in the development of modern industry, but also can not be replaced by a material, I hope we explain today about some knowledge of the product, can bring you some help.

Insulation rubber sheet https://www.sincererubbertech.com/Insulation-rubber-sheet.html